From processing yarn to fabric and from fabric to garment, we manage every step of the production process at our factories.

Our production facility spans:

Factory Area: 100000 sq. ft.

Factory Production Capacity: 5,000 - 8,000 pieces per day

We are confident of handling large quantities and are flexible to meet any production requirement. Fulchand offers its customers a range of quality garments in both select and volume quantities along with a custom-calibrated production line:

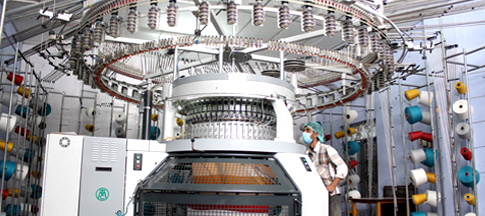

Fulchand offers knitting for all structures of fabrics from yarn dyed stripes to the most complex jacquard designs. We have 30 German made state-of-the-art MAYER & CIE knitting machines, which can manufacture single jersey/interlock/rib/auto-striper and fleece fabrics. Additionally, we have 7 flat collar SHIMA - SEIKI MACHINES, for all types of design.

We work with the high-precision German-made ASSYST BULMER automatic cutting machines, and also use the WASTEMA , band knife fabric cutting machine. The cutting machines are supported by the IMA fabric spreader. We use CAD/CAM software called ORBITO , which is used for precise pattern making. These advance technologies enable us to handle high volume of fabric cutting with precise consistency.

A unique creation comprises variety of embroideries, with different specs, colors and threads. We work with BARUDAN and TAJIMA machines and have a total of 40 heads. We also have 8 head machines that provide support for sampling. This combined with our expert team can fulfill your order with care.

Our highly trained/skilled tailors ensure that you get the best in garmenting. We have one of the best-computerized stitching (YAMATO , BROTHER, JUKI, TYPICAL) machines. We successfully handle production that involves various different operations ranging from – single needle to complex fancy stitches. We have a total of 200 stitching machine.

We ensure that all the garments follow consistency in measurements, and as leading garment manufacturers have the expertise to meet your precise deliverables. For this, we work with some of the leading brand names like NAOMOTO, MACPI and BELLA. These machines help trim excess threads, remove stains (if any), and steam iron.

We ensure that all the garments are monitored for quality at every stage. Our quality team is well versed with the AQL 1.5 level of inspection. Our quality process includes fabric checking, initial, middle, online and final inspections. We also have a complete lab set-up, where we test for GSM, shrinkage, spirality, color fastness of the fabric, prints, embroideries and trims.

Our infrastructure and management is organized through an ERP system, which helps us with production management and control.